3D printing is recognized as one of the most promising inventions of all time. The many things that can be accomplished with a 3D printer are amazing. With its ability to print layers and dimensions, this technology has changed how products are being created by reducing the errors in development.

Apart from its ability to produce a top-notch product sample or mock-up, the technology offers significant advantages such as reduced costs, reduced time in product manufacturing and production, offers a competitive edge, reduce errors and promotes production on demand. Better yet, it doesn’t need trained designers or engineers to use this technology, which is why more industries use 3D printing for their business operations.

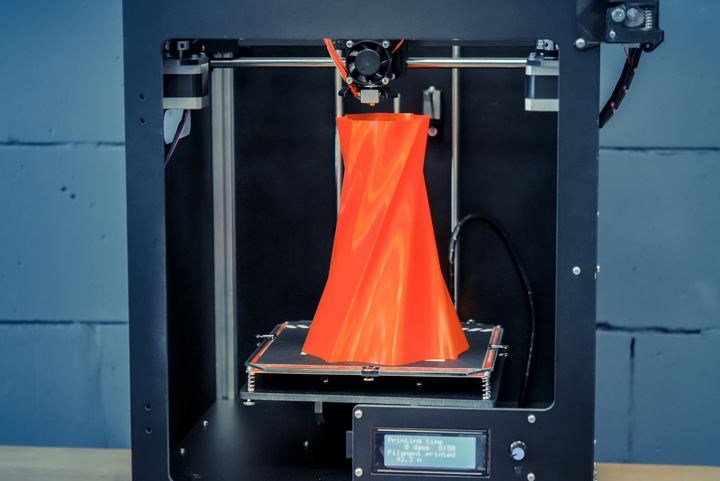

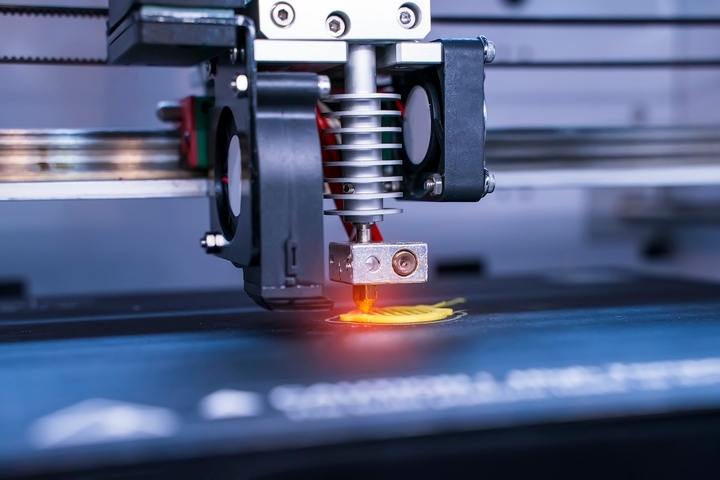

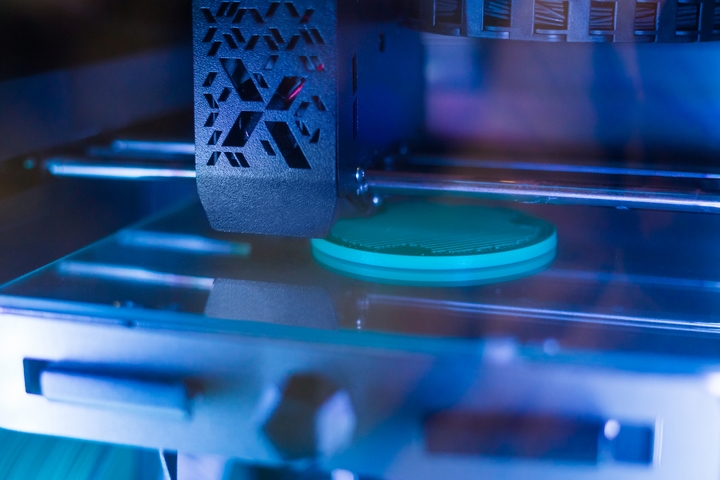

Ever wondered how this technology works? Well, in the case of the 3D printer, the first step involves the creation of a digital file or image that the technology uses to build layers at a time from ground up. The 3D printer uses various materials rather than ink, such as molten plastic or powder, that fuses the layers. In a few hours, it turns the drawing into a dimensional and cross-sectional object.

Many industries are benefiting from 3D printing technology that have improved their business operations for the better. Below are eight popular industries that use 3D printing for business:

1. Jewelry Industry

The jewelry industry is benefiting from the 3D printing technology as the digital tools offer personalized creations and better services for customers. Today, jewelers can discuss the design with a customer and use the 3D printer to create a physical model of the jewelry piece quickly.

This has drastically reduced the feedback time between the designer and the customer. And it has also reduced the time it takes to produce these customized jewelry units. With the 3D printer, jewelers can create complex jewelry pieces that would otherwise be difficult through the traditional hand carving method.

2. Automotive Industry

3D printing technology is transforming the automotive industry by leaps and bounds. This technology is helping the industry create complex parts as well as enhance measurement and testing. Every vehicle involves a detailed design and development process. Engineered parts have to be tested for weight, structure, integrity and aerodynamic suitability.

It took a lot of time to produce prototypes in the past, and if the parts didn’t work out, then the prototype would go through another full cycle. Thanks to the 3D printing technology, prototypes can be completed within weeks and with greater detail.

3. Manufacturing Industry

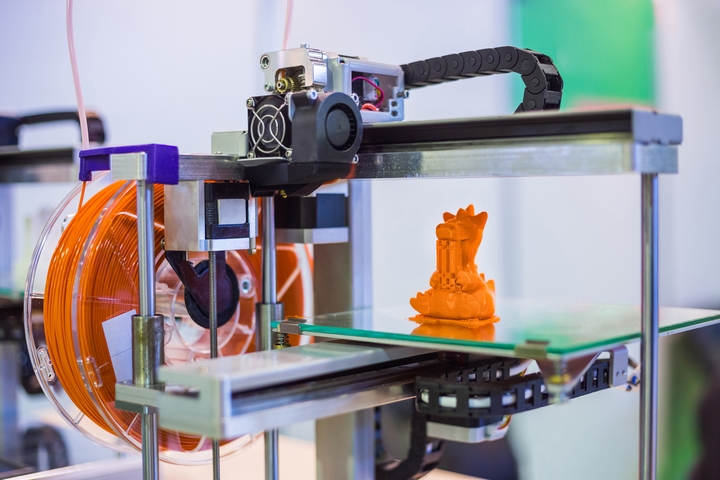

3D printing has significantly influenced the manufacturing industry and processes. It is a needed technology in manufacturing as it saves on material costs, production time and prototypes.

Traditional manufacturing methods are expensive because different machines are required during the manufacturing process. This expense is removed with 3D printing. It has also improved the time to market a product.

4. Dentistry Industry

The dentistry industry uses 3D printers more and more frequently. This industry requires a high level of customization and details for crowns, dental implants and clear aligners. 3D printing has not only improved the details of a dental structure, but it has prevented wasted materials in the production of these structures.

The use of 3D printing is relevant for this industry as it improves the dentists, orthodontists and prosthetists’ daily work.

5. Aerospace Industry

The aerospace industry has been leveraging 3D printing for many years. This technology has helped aerospace companies develop lighter parts without compromising on strength and structural integrity.

Apart from this, the technology has alleviated supply chain constraints and material wastage. Now the industry can produce parts on-demand that have resulted in greater efficiency. In fact, aerospace companies are not limited to just prototypes; they can even create real, functional parts through the 3D printer.

6. Robotics Industry

3D printing has made the robotics industry thrive. With this technology, companies can build prototypes very quickly. The parts of a 3D printed object can be easily improved, enabling error-free developments of the actual robot or machine.

Combining 3D printing with industrial robotics offers a novel and promising approach to the manufacturing of these sophisticated machines.

7. Education Industry

3D technology can impact learning. It is important in two ways. First, it will become an important technology in the future that will lead to profound economic changes. Second, it will enhance learning for various fields such as dentistry, automotive and aerospace.

3D technology has to be incorporated in education to prepare students for future developments and for them to be able to adapt to the technology at the workplace.

8. Architecture Industry

3D printing is reshaping the field of architecture. This technology is the perfect tool for architects as they can create a tangible model of their design. Every architect wants to develop a concept model so that the client has the opportunity to visualize the idea.

3D printing helps in creating the exact model, including complex geometries. And because the technology is simple to use, architects can complete more designs and produce models efficiently in a shorter period.